LFAM 3D Printing Services Large‑Format Pellet Manufacturing

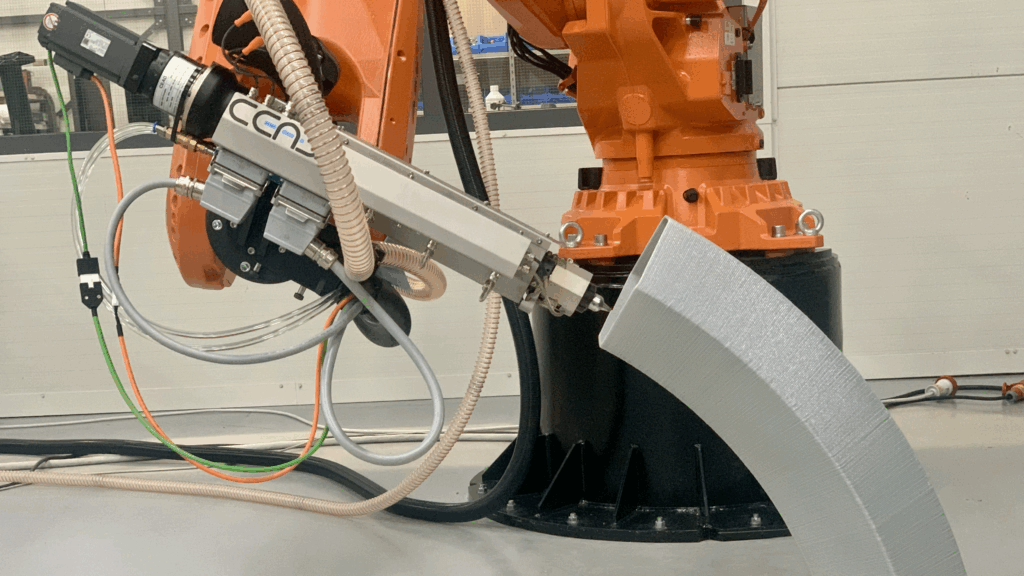

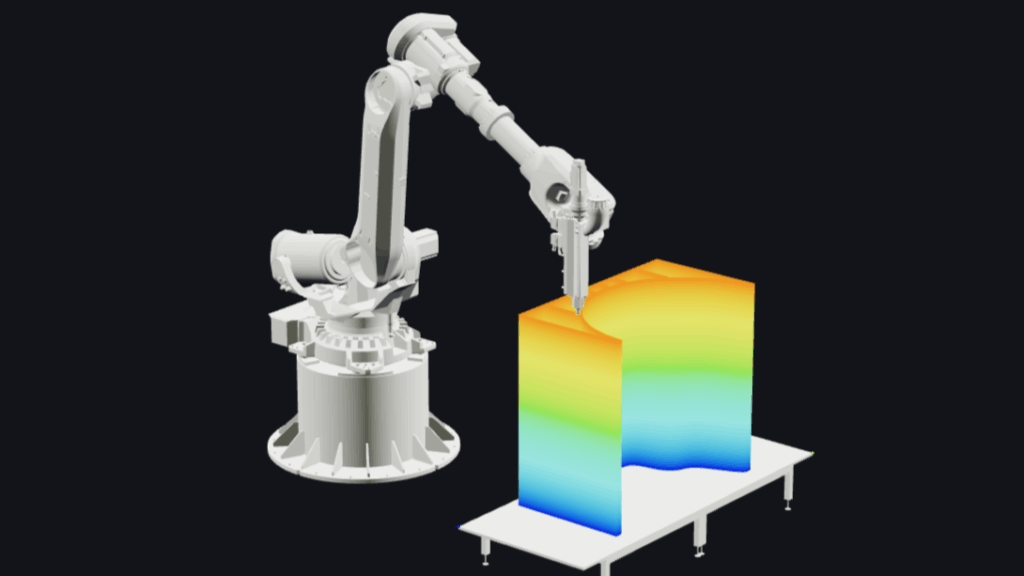

When your part is too big for conventional printers, Large‑Format Additive Manufacturing (LFAM) delivers. Our multi‑axis robot cell extrudes industrial thermoplastic pellets at very high flow rates, producing metre‑scale molds, patterns, and end‑use structures in days instead of weeks—without expensive tooling.

Design Freedom at Scale

Robot‑guided pellet extrusion follows free‑form paths, so you can create sweeping curves, undercuts, and internal channels impossible with traditional large‑format methods.

Fast Turnaround, Lower Costs

High‑throughput pellet extrusion and minimal material waste let you receive metre‑scale parts in days, often at a fraction of CNC‑machining or composite lay‑up costs.

Industrial & Recycled Pellets

Choose from virgin, reinforced, or recycled PP, PETG, ABS, PA and more—balancing performance, weight, and sustainability for every project.

Large‑Scale Production Tooling

Print lightweight molds for thermoforming, vacuum forming, or composite lay‑up—ready for a quick CNC skim and immediate factory use.

Technical Specifications – LFAM Robot‑Arm Cell

Specification

Details

Build Volume

Standard builds up to 2 × 2 × 2 m. With our 3.2 m‑reach robot on a 0.7 m pedestal, optimized paths let us print parts as large as ≈ 3.5 m H × 5 m W.

Layer Height

0.5 mm – 10mm

Nozzle Diameter

Standard: 4 mm (Optional: 2 mm, 6 mm, 9mm, 12mm, 15mm, 18mm)

Extrusion Rate

12 kg per hour (nozzle & material dependent)

Supported Materials

PP, PETG, ABS, ASA, PA, PC, TPU, glass/carbon filled & recycled pellets, others on request

Colors Available

Wide range available; custom colors on request

Tolerance

± 1 mm (varies with material, nozzle size and part geometry)

Supported File Types

STL, STEP, OBJ

Lead Time

From 3–8 working days, depending on part size and quantity

Need a Part That Won’t Fit Anywhere Else?

Send us your design for a fast LFAM quote and discover how large‑format pellet printing can shrink costs and timelines on your next oversized project.