SLS 3D Printing Services

Create strong, lightweight parts with our Selective Laser Sintering (SLS) technology. The self‑supporting powder bed eliminates the need for support structures, enabling complex geometries, lattice infills, and cost‑effective batch production for both prototypes and end‑use components.

Production‑Ready Nylon Parts

SLS delivers isotropic strength and heat resistance, ideal for prototypes, housings, and functional end‑use components.

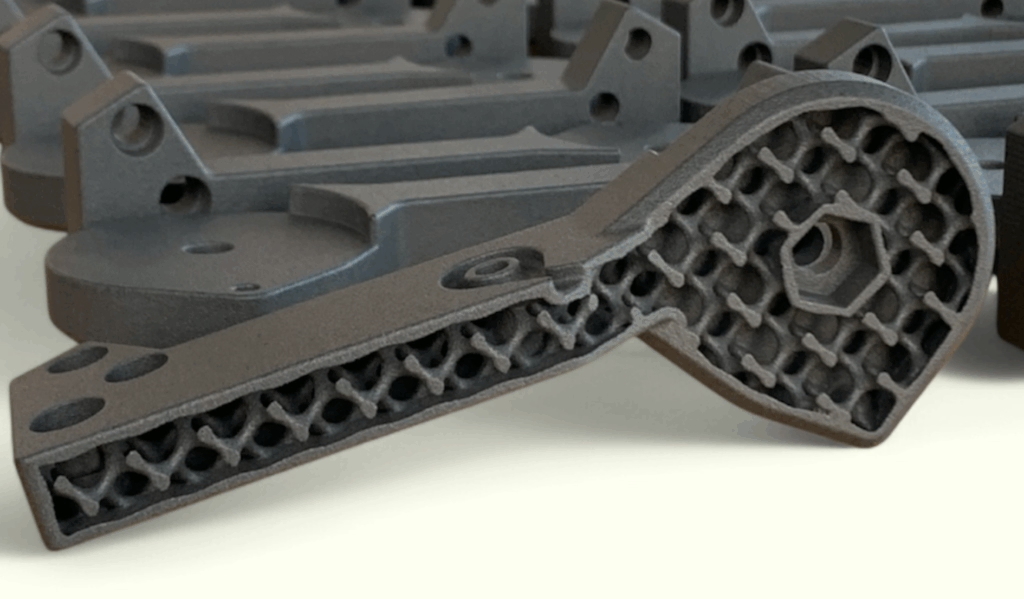

Complex, Support‑Free Geometry

Print internal channels, lattice structures, and nested assemblies without extra supports, unlocking design freedom that traditional methods can’t match.

Industrial Powder Performance

Engineering‑grade powders provide reliable mechanical and thermal properties, making SLS a versatile choice for demanding applications.

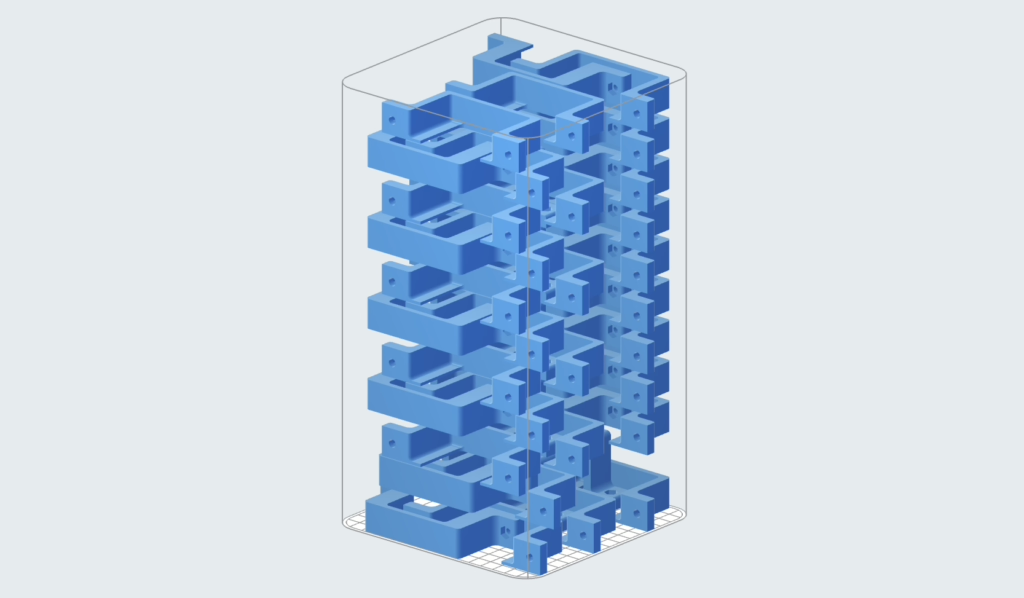

Efficient Batch Production

High packing density lets us nest multiple parts per build, reducing cost per unit and shortening lead times.

Technical Specifications – SLS 3D Printing

Specification

Details

Build Volume

Up to 160 × 160× 300 mm

Layer Height

110 µm

Supported Materials

PA12 (Nylon 12), others on request

Colors Available

Dark Grey, parts can be dyed black or custom colours after printing

Tolerance

± 0.3 mm (varies with material and part geometry)

Supported File Types

STL, STEP, OBJ

Lead Time

From 1–5 working days, depending on part size and quantity

Ready for Strong, Support‑Free SLS Parts?

From rapid prototypes to production‑ready nylon components, our SLS experts are here to help. Send us your files for a fast, no‑obligation quote and discover how support‑free powder‑bed fusion can accelerate your project.